General Motors has filed a patent application for wheels made from a combination of metal and composite material, which the automaker claims could reduce weight and materials cost.

Most production-car wheels are made from aluminum or steel, and are usually cast or forged as a single piece. The patent application, which was published by the United States Patent and Trademark Office (USPTO) on Oct. 10, proposes two-piece wheels made from metal and fiber-reinforced polymer (FRP) composite.

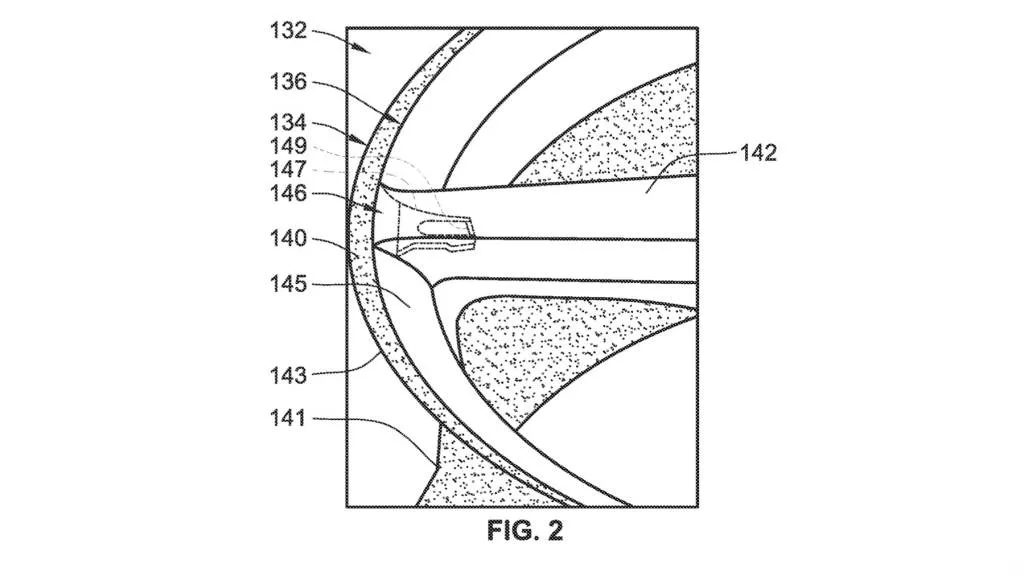

General Motors hybrid metal and composite wheel patent image

As described in the application, the wheel barrel would be metal, while the wheel face and spokes would be made from FRP, which could include carbon fiber as part of its composition. The spokes could also be made hollow, making room for metal inserts for added stiffness.

The metal barrel and composite could be attached using adhesive, metal fasteners, or by over-molding the composite piece. In this case, material would flow into pre-made holes or slots in the metal wheel barrel as the composite piece is molded into shape.

General Motors hybrid metal and composite wheel patent image

Some performance cars, including GM’s own Chevrolet Corvette Z06, already offer carbon-fiber wheels that are lighter than equivalent metal wheels. But GM believes the hybrid design will provide better impact resistance, durability, and repairability by keeping the more damage-prone barrel section metal.

These wheels would also have an appearance similar to all-carbon-fiber wheels, including the possibility of exposed-carbon spokes, according to GM, adding that the composite wheel face offers more freedom to designers. But while it seems like a sensible compromise, there’s no guarantee that a hybrid-material wheel will reach production. Patent applications are not product plans.