- VW’s unified EV cell format brings cell-to-pack battery design

- Cuts costs, sets stage for cell-to-body and simplified EVs

- Means EVs with more range and energy density, perhaps lower weight

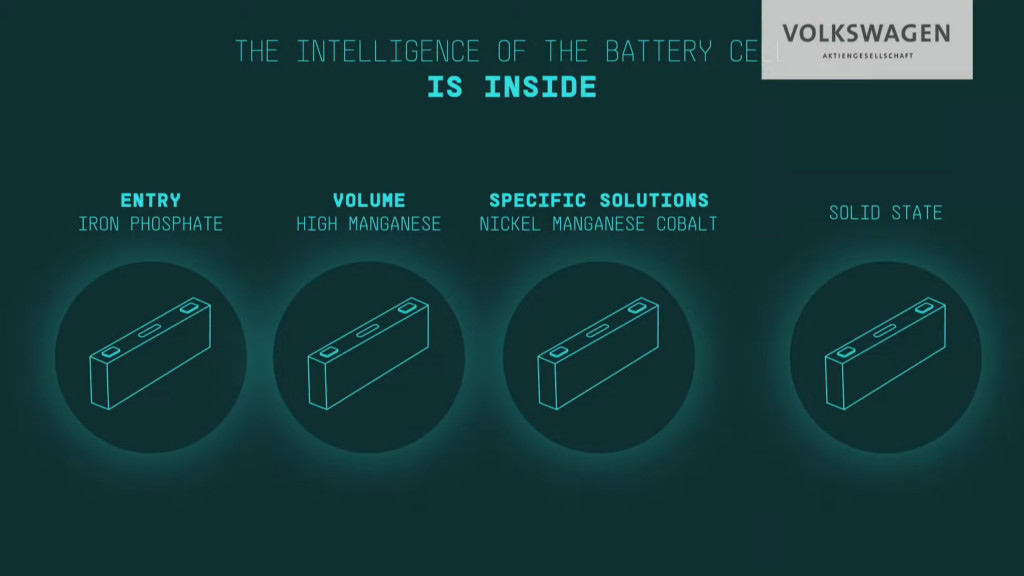

- LFP and NMC chemistries on the same format, maybe solid-state, sodium-ion

Volkswagen’s vision of where it might be by the end of the decade with electric vehicles has evolved in recent years. But simplification is the keyword, and its plans to focus on a single EV battery cell format go right along with that.

This week, in a technology update held just before the company’s Volkswagen Group Annual Conference, the global automaker and its battery-making PowerCo startup shared a closer look at how these unified cells will be packaged in upcoming EVs from VW, Audi, Cupra, and several of its other brands, in the near future.

As these unified cells arrive—soon, but on a timeline not yet detailed, especially for U.S.-market EVs—they’ll bring a new battery pack layout, packaging the cells directly into the pack. This allows more energy density, as well as a lighter pack, said VW officials, and the approach allows VW to be more flexible with versions for different models and markets.

Current MEB battery pack layout

VW EVs set to move on from modules

Today’s electric vehicles built on VW’s MEB EV foundation, including the ID.4 and ID.Buzz, incorporate shoebox-sized modules of pouch cells integrated into the battery case (above). But as VW outlined this week, the next-generation battery arriving as soon as late this year for Europe will have the cells directly mounted into the battery housing—essentially in four rows spanning longitudinally along the battery case in the example shown (pictures of the demonstration case weren’t allowed).

The battery pack case evolves somewhat to accommodate the cell-to-pack layout, with the mechanical ribs that act as attachment points for the modules reduced while reinforcements have been added elsewhere.

Battery pack layout with cell-to-pack

Current MEB battery pack layout with module-to-pack

Cooling has been completely reworked for the new cell type and arrangement. The flat faces of the cells allow easier temperature control, and the housing on the outside has been completely reworked—with the most noteworthy change appearing to be a pattern of narrow cooling channels over a top plate. It’s not unlike the cooling approach to be used in Honda’s 0 Series EVs (although those will have modules).

At the cell level VW will not only monitor cell voltage but also temperature. The battery management system remains of the wired (versus wireless) type.

2025 Volkswagen ID.Buzz

Potentially more range in MEB models—like ID.Buzz?

Officials also said that there’s potential for longer packs with “way bigger energy content” versus the current capacity—maxed out at 91 kwh (or 86 kwh usable) with the pack in the Euro-market ID.7 and U.S.-market ID.Buzz, currently the two longest MEB vehicles.

DriftBreath Reports reads that as a pretty strong suggestion the Buzz could gain more range within the next few model years, as it simply needs it in order to match its road-trip mantra—although VW officials wouldn’t say so much.

Although Volkswagen confirmed the battery strategy as on the way for its ID.2 and ID.1 EVs arriving in Europe over the next couple years, it suggested that the non-extended-length demonstrator we saw compared roughly to the 82-kwh (77-kwh usable) pack in today’s ID.4.

Officials emphasized that exact figures for battery capacity, energy density, weight, and more will be released at the IAA Mobility 2025 auto show, set to be held in September in Munich. As shown, the preliminary pack is 400-volt, but more details about that and charging are also forthcoming at IAA.

2024 Volkswagen ID.4

At the core: EV cost-cutting

As for these cells themselves, they’re a key piece in VW making a move to lower cell costs and enable more affordable EVs.

“The unified cell format built according to our own global and uniform technology standard will be the basis for massive economies of scale in cell and battery systems,” said Michael Steiner, head of research and development for the Volkswagen Group, at the event.

Steiner said that EV batteries still account for more than a third of EV cost—so the cells represent competitiveness not just on cost but on performance versus vehicle weight.

Development of the unified cell format was done at VW’s Center of Excellence for Battery Cells in Salzgitter, Germany. The facility oversees battery strategies, development, and purchasing, and it has a responsibility for nearly all aspects of battery technology.

The unified cell format aims to reduce the complexity of battery systems and cells, and that also goes to optimize battery costs and enable lower entry prices for volume segments of the market. It’s also part of an effort to coordinate the technology needs for China, Europe, and North America.

VW Power Day – battery types

Flexible chemistry, from LFP to sodium-ion to solid-state

It also permits the adoption of multiple chemistries with the same cell format, allowing for a volume NMC (nickel manganese cobalt) cell along with LFP (lithium iron phosphate). And it can not only accommodate the cell types VW has developed on its own but also next-generation sodium-ion or solid-state chemistries. A 2024 agreement between PowerCo and the solid-state battery tech firm QuantumScape, for instance, allows PowerCo to make up to 40 gigawatt-hours of solid-state lithium-metal cells annually, with the option to double that to 80 gigawatt-hours. The companies involved haven’t detailed a timeline

They’re also almost here—the NMC ones, that is. VW presented its plan for the unified cell format four years ago this month. It promised then, in 2021, that it would ramp up production of these unified cells around 2025, in a small volume at first, and it’s delivered exactly that.

VW unified cell format

PowerCo says it has already produced over 100,000 cells and successfully tested them. That’s at its location in Salzgitter; PowerCo has two other production locations in the works, in Valencia, Spain, and in St. Thomas, Ontario (Canada). Valencia and Ontario are both due to ramp up in 2026.

Volkswagen has already said that its Salzgitter factory will have a target volume of 40 gigawatt-hours per year—enough for approximately 500,000 EVs. And altogether, the three factories are due to produce up to 200 gigawatt-hours of cells annually.

VW EV platforms and E/E architectures

How it all fits together: SSP + SDV + …cell-to-body?

VW is in the midst of massive change, as it embarks on a master plan that aims, over the next few years, to consolidate a range of different platforms and several electrical and electronics architectures down to a single modular Scalable Systems Platform (SSP) plus a software-defined vehicle approach that will utilize Rivian’s zonal architecture and reconceive everything from how zones are defined to the vehicle interface itself.

Neither the production-bound ID.Every1 (below), previewing a sub-$25,000, nor the production-bound, sub-$30,000 ID.2all, which is coming before that, are U.S.-bound. The ID.1 is set to use “elements” of the Rivian-derived zonal architecture, mated with a number of MEB components carried over.

Volkswagen ID.Every1

SSP will arrive in full form in the ID Golf, which is due around 2028, VW says. That’s still a far-off possibility for the U.S., although SSP will soon after that propagate to a wide range of models, types, and brands from the whole group.

And the next stop, VW’s battery people say, is cell-to-body tech—in EVs that were designed from the start to incorporate battery cells directly into the body. VW’s SSP will reportedly enable this, although it’s yet unclear whether some or all vehicles on the platform will offer it and when.

What also still remains uncertain is how quickly VW intends to migrate its internal combustion models to a similar modular and software-defined approach, especially now that it might focus more on hybrids or plug-in hybrids for North America.

And in the meantime, how quickly it migrates its current MEB EVs like the ID.4 and ID.Buzz to this seemingly incremental battery-format makeover could end up providing a big boost to their range, and appeal.