As the mobility and EV industry converges around a seemingly limited array of battery sizes and just three form factors, California-based Sakuu is suggesting a very different, seemingly endless range of possibilities—like future cells sized and shaped for products.

The manufacturing hook behind this proposition is 3D printing. While there have been a few attempts at 3D batteries before, Sakuu claims that as of December 2022 it’s the first “company of record to 3D-print fully functional batteries in custom shapes and sizes with patterned openings for thermal management in a completely dry process.”

The company says that it’s on track to make printed batteries at scale for mobility, aerospace, EVs, and energy storage, among other uses—and the benefit from first look is that the cell design can follow the product design, rather than vice versa.

It doesn’t say what the energy density of these first cells is, but it promises impressive figures by volume. It claims “expectations are to achieve high energy density at 800–1000 Wh/L.” That’s indeed higher than the current generation of lithium-ion cells used in EVs—and even what’s been targeted by Panasonic, for instance, by 2030.

Flexibility away from skateboards

In the not-too-distant future, such custom-shaped cells might bring opportunities for electric vehicle engineers and designers who today have converged on the “skateboard” battery layout—body over a thin battery brick—as the package with the least compromise.

Such batteries might allow certain portions of the body structure itself in EVs to be filled with uniquely shaped battery cells rather than left empty, altogether comprising a mass-less battery of sorts, and freeing up passenger-car and coupe bodies to be lower, leaner, and sleeker.

In the electric car realm, that could mean that designers and engineers might be able to curb the inherent compromises of a skateboard.

Sakuu 3D-printed battery cells

With the announcement, Sakuu has shown a demonstration single-layer cell, which it could then stack with many others, connecting them in series or parallel as needed, to form a pack. Two holes show where coolant passages would run within a pack.

Different process than all the battery factories

Sakuu uses a dry cathode process and a single platform printing machine, and it emphasizes that this is not a wet screen printing process, which uses excess energy to remove solvents and can be unreliable.

Nor is it anything like the roll-to-roll process that is used to make most battery types. The company, in what’s also called additive manufacturing, constructs super-thin layers at a time, applying multiple materials as part of the same layer.

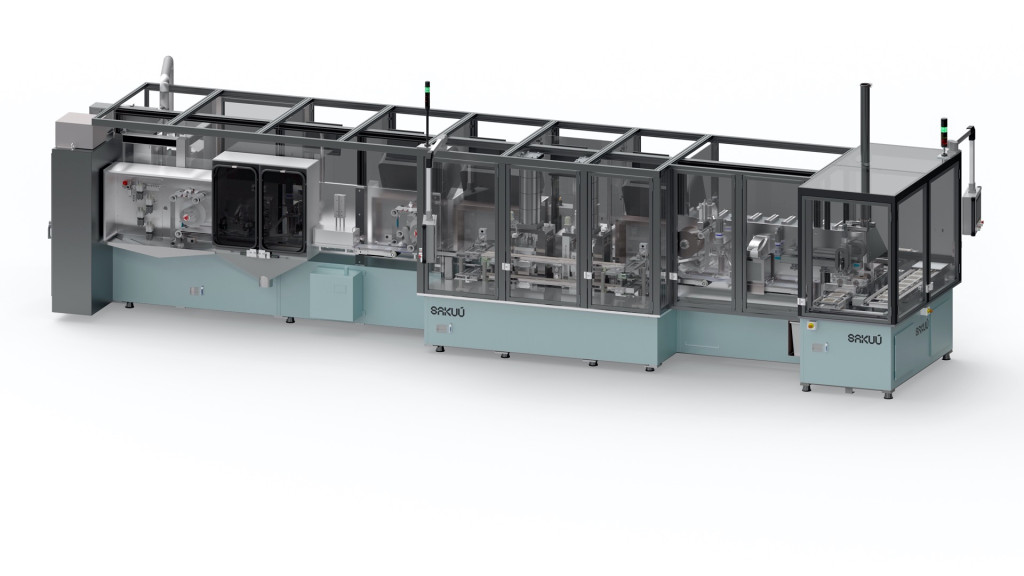

Sakuu, which was founded in 2016 as KeraCel and was rebranded in 2021, opened a 79,000-square-foot development facility for its manufacturing platform in San Jose. It promises “world class energy and power densities at production speeds comparable to the best roll-to-roll manufacturing equipment,” and it claims it has the only known manufacturing solution to produce solid-state batteries at commercial scale.

The company aims to license its battery chemistries as well as sell its manufacturing platform, which it wants to see used to make 200 gigawatt-hours of cells by 2030 through “global partner gigafactories.”

Porsche Consulting has said that it will design the battery maker’s 3D-printing gigafactory for mass production of the tech. Sakuu confirmed to DriftBreath Reports that the renderings here are of pilot production equipment already in use.

Sakuu 3D-printed battery cells

Speeding up solid state?

The firm’s technique could help spur the production of solid-state cells sooner, and it might potentially enable higher energy densities, by allowing thinner battery cell layers, so as to fit more in a given format and space.

There are many other theoretical advantages of solid-state batteries, including faster charging and higher performance, as well as, depending on how they progress as they move to mass production, greater durability and less degradation.

In the solid-state field, there’s no shortage of rivals. In addition to the battery establishment, a host of firms including Factorial, StoreDot, and QuantumScape claim to have an advantage in this battery revolution. Nissan is also one of several automakers working on its own solid-state cells. It’s also aiming for a dry process, but with a traditional layered approach to the cells, albeit with some materials tricks such as a meshlike binding between active material and solid electrolyte.

Sakuu currently has two battery-chemistry lines in development, a lithium-metal, and an all-solid-state lithium-metal. While it won’t disclose other details regarding those chemistries, it says that both use the company’s 3D-printing-based manufacturing approach.

Sakuu 3D-printed battery cells

3D printing techniques have countless uses in the automotive realm, from reprinting unavailable parts for older Tesla Roadsters, to the creation of electric motors made of 3D-printed parts, to an entire Cadillac Celestiq EV flagship made possible with 3D printing techniques.

From an environmental angle, there may be some additional advantages. 3D printing tends to use less material versus traditional manufacturing methods, by the very nature of the additive process it uses. It also typically requires less energy. With 3D printing, targets for cost, the supply chain, and carbon footprint might be met sooner.